Fence

Weaving a fence

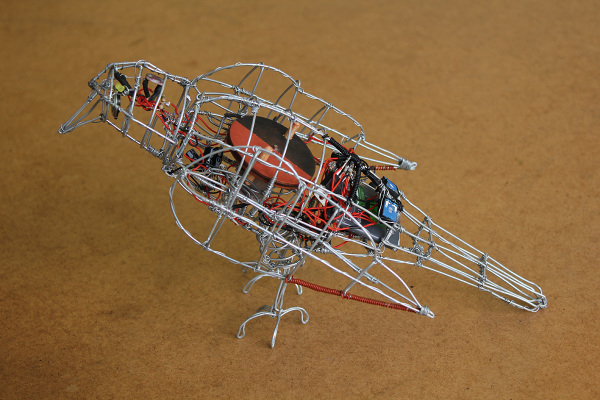

The process I undertook during 2005 was the production of nine separate sections of chain-link fence fabric. Each section measured 2,4 x 0,8 meter and was made with wire ranging from 0.3mm to 0.6mm. The work was produced using as little mechanical interventions as possible, resulting in a low-tech time and labour intensive process. The tools utilized: masking tape, long-nose pliers, hammer, hand-punch, electric-drill, tape measure, two sets of gloves (PVC coated/ cotton), more than 4 kilograms of nails (1,6mm x 25mm and 2mm x 32mm), 1,5mm drill bits. The majority of these tools were used to construct a “loom” that was necessary for weaving the fence.

On individual authorship of work – to me the work became a personal and isolating process. The idea is of manual mass production or more specifically, individualizing a process that is commonly mechanized. Solely I undertook the process to produce the end product. The reason being that the toil and labour of a single individual has an interesting effect on the viewer’s perception of the output. This idea of “relative magnitude” in effect forces it to read differently than one would have that of work produced by a group. The exception is certain things like the materials which had been purchased: the purchase of wire, nails, Masonite board was necessary as there would not have been enough time to personally manufacture each, although it would have added an interesting element if I had single-handedly done everything.

The idea of the machine-made to the man-made: imperfections remove it from the realm of machine-produced to the hand-made. Constructing the wire-mesh myself has allowed for the possibility of the object being visibly not machined. Deviations from the diamond-mesh pattern of chain-link fencing is seen both to animate the surface and allow re-enforcement of fabric in weaker areas.

– Fabian Saptouw, 2014